Slide Gate Valves

Ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications. Vortex slide gates are designed and engineered with two main principals in mind: 1. extend the service life of the valve and 2. perform maintenance without taking the valve out of line. Vortex valves serve many industries including chemical, cement, coal, food, frac sand, grain, minerals, petrochemical, pharmaceutical, plastics, polymer, rubber, and mining.

Orifice Gate

The Vortex® Quantum Orifice Gate™ is specifically engineered to handle dry bulk solids in gravity flow, dilute phase, or vacuum conveying systems with pressures up to 15 psig (1 barg) depending on size. Traditional slide gates and butterfly valves commonly allow packing of material, which prevents positive air and material shutoff.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

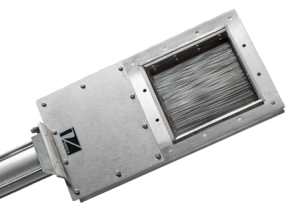

Roller Gate

The Vortex® Roller Gate™ is the best choice for handling dry material in gravity flow or low-pressure applications. This gate is available in a wide variety of configurations including rectangular sizes and customer specific hole patterns. It has live-loaded seals that extend the service life by compensating for wear. These seals provide an excellent material seal across the gate and to atmosphere. They can also be replaced while the valve is in-line. Similar slide gates have seals made of soft packing, rubber or felt, which rapidly erode away allowing product leakage.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

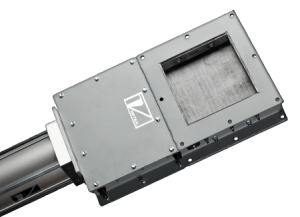

HDPV2

Designed to address higher-pressure applications up to 75 psig (5 barg) depending on size, the Vortex® HDPV2™ sets itself apart from traditional industry slide gates. The rising blade design provides positive material shut-off by means of an O-ring seal on the inlet of the valve. This design feature eliminates the issues related to packing of material causing abrasion to the end seal.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

TSG Gate

The Vortex Titan Series TSG Gate is designed to meet the most demanding applications when handling heavy-duty abrasive materials such as sand, gravel, coal, and whole grains. The TSG Gate handles dry material in gravity flow applications where positive material shut-off and dust tight sealing is required. This slide gate is available in a wide variety of configurations with rectangular sizes and customer specific hole patterns.

Key Industries Served: Agriculture, Chemicals, Minerals, Mining, Petrochemicals, Plastics, Textiles

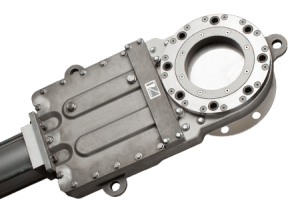

TPV Gate

The Titan Pressure Valve is designed to address higher-pressure applications up to 100 psi (6.8 barg) and higher temperatures up to 660° F (350° C). The TPV Gate is engineered for highly abrasive applications and requires minimal maintenance over the life of the valve. Featuring Vortex’s rising-blade technology, the TPV Gate ensures an optimal seal and positive material shutoff with the use of lifting lugs. This prevents the blade from jamming or packing material upon closure, which can cause serious downtime. Unlike most knife gates, the Vortex TPV contains a replaceable seat that can significantly increase the life of the valve.

Clear Action Gate

The Vortex® Clear Action Gate™ is designed for use in gravity flow or pneumatic conveying systems up to 15 psi (1 barg) depending on size. Mounted horizontally, the machined square-edged blade of this gate mechanically clears the material from the sealing surfaces on each closing cycle allowing it to discharge beneath the valve. Open cavities where material collects in traditional gate valves have been eliminated with the square blade and seal design.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Aggregate Gate

The Vortex® Aggregate Gate™ is designed to meet demanding applications handling material such as sand, gravel, whole grains, and coal. The narrow profile, choice of actuators, and custom rectangular sizes make this slide gate adaptable to most existing installations. Optional inlet or outlet flanges and dust return pans are available.

Key Industries Served: Agriculture, Chemicals, Minerals, Mining, Petrochemicals, Plastics, Textiles

RBG Gate

The Vortex RBG Gate (Rounded Blade Gate) is designed to meet the most demanding applications when handling heavy-duty abrasive materials. The RBG Gate handles dry material in gravity flow applications where positive material shut-off and dust-tight sealing is required. The design of the gate allows for rapid actuation to quickly start and stop material flow and makes it a good choice for dry bulk applications that require metering.

Key Industries Served: Agriculture, Minerals and Mining

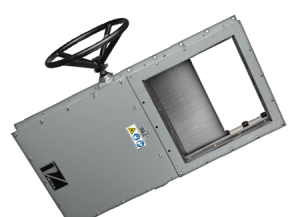

Maintenance Gate

The Vortex® Maintenance Gate is designed to shut off material from a hopper or silo when maintenance of downstream equipment is required. In the open position, it positively seals conveying air and material to atmosphere. The hand crank gearing is designed to close through material in case of an upset condition.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Hand Slide Orifice Gate

The Vortex® Hand Slide Orifice Gate™ is designed specifically to handle dry bulk solids in gravity flow conveying. A full flow orifice provides unrestricted conveying of material with no disk or ledges to impede flow or cause material bridging. The gate seat and live-loaded seals are protected from material flow by a metal insert. By design, the valve “self cleans” material from the seat on each stroke of the valve blade improving overall seat life.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Quick Clean Orifice Gate

The Vortex® Quick Clean Orifice Gate™ is a “clean out of place” gate valve designed for frequent cleaning. The valve features a full-port opening and self-cleaning design. It can be disassembled and assembled in minutes without tools. The valve carries a USDA Dairy Standard Accepted rating and is an excellent choice for sanitary applications.

Key Industries Served: Chemical, Dairy, Pharmaceuticals, Pigments

Diverter Valves

Ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications. Vortex diverters are designed and engineered with two main principals in mind: 1. extend the service life of the valve and 2. perform maintenance without taking the valve out of line. Vortex valves serve many industries including chemical, cement, coal, food, frac sand, grain, minerals, petrochemical, pharmaceutical, plastics, polymer, rubber, and mining.

Wye Line Diverter

The Vortex Quantum Series Wye Line Diverter is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressures up to 15 psig (1 barg) depending on size. A full flow orifice provides unrestricted conveying of material. The live-loaded seals are shielded from abrasion by a metal insert

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Seal Tite Diverter

The Vortex Seal Tite Diverter is designed for use in gravity flow applications where material can be diverted from one source to either two or three destinations. The Seal Tite Diverter offers a removable access door for interior inspection, cleaning and maintenance.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles

Flex Tube Diverter

The unique design of the Vortex® Flex Tube Diverter™ eliminates material cross contamination through a positive seal across the closed port. Pockets where material can lodge and remain trapped have also been eliminated. A smooth unobstructed transition from inlet to outlet shields the wear compensating seals from abrasion.

Key Industries Served: Agriculture, Chemicals, Foods, Minerals, Petrochemicals, Plastics, Textiles