Valve bag fillers

Valve bag fillers displayed on this page are well suited for both manual and automated applications ranging from building products and minerals to seed and food products.

Model 121 Spout Integrated Ultrasonic Valve Sealer

For Sealing Thermoplastic Lined Paper & Poly Valve Bags

Model 230 Spiral Flow Auger Valve Bag Filler

For Dusty Powders, Powder & Granule Mixes & Semi-Free Flowing Powders

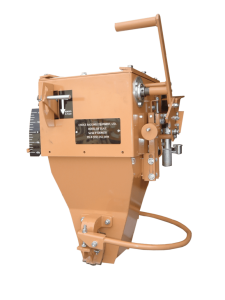

Model 720 Plug Flow Air Packer

For Powder & Granule Blends and Granular Products (Especially Abrasive Materials)

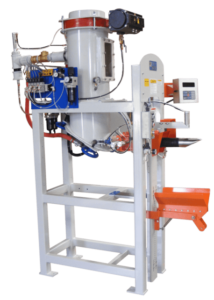

Model 730 Pressure Air Flow Packer

For Fine Powders, Powder & Granule Blends and Granular Products

Model 830 Paddle Flow Impeller Packer

Fine Free Flowing Powders (100 Mesh & Down) Between 50-100# Per Cu. Ft.

Model 930 Horizontal Impeller Packer

Fine Free Flowing Powders (100 Mesh & Down) Between 15-50 Lb. / Cu. Ft.

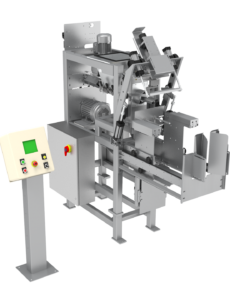

Model 1000 Fully Automatic Valve Bag Placers

For Automatic Placing of Block Bottom Paper & Poly Valve Bags

Open mouth bag fillers

Open mouth bag fillers are very simple, fast filling and easy filling of both food grade and non-food grade materials.

Model GB Mechanical Gravity Open Mouth Bag Filler

For Granular, Free Flowing, Non-Dusty Products

Model GWB-GV Gravity Vibrator Open Mouth Bag Filler

For Granular, Free Flowing, Non-Dusty Products

Model GWB-AF Auger Fed Gross Weigher

For Free Flowing, Semi-Free Flowing & Floodable Powders

Model GWB Digital Gravity Open Bag Mouth Filler

For Granular, Free Flowing, Non-Dusty Products

Model GWB-BF Belt Fed Gross Weigher

For Course, Semi-Free Flowing & Non-Free Flowing Materials

Model NWB Net Weigh Filler

For Filling Bags, Boxes, Pails & Drums with Granular (80 Mesh or Courser), Free Flowing, Non-Dusty Products

Bulk bag fillers

Bulk bag fillers are a very efficient, fast filling and economical method of packaging both agricultural and industrial materials. They can be designed to operate as either manual or automated systems

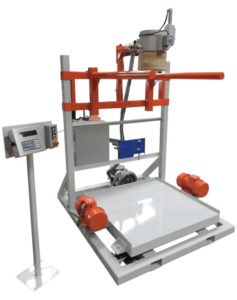

Model 510 Bulk Bag (FIBC) Filler

For All Types of Powders & Granules (for Applications with Production Requirements of 1-6 Bags per Hour)

Model 520 Bulk Bag (FIBC) Filler

For All Types of Powders & Granules (for Applications with Production Requirements of 5-20 Bags per Hour)

Model 530 Bulk Bag (FIBC) Filler

For All Types of Powders & Granules (for Applications with Production Requirements of 5-25 Bags per Hour)

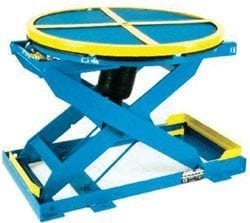

Bulk Bag UNloaders

Heavy Duty Bulk Bag Unloading System Designed to Discharge & Condition 1,000-4,400 lbs Bulk Bags with Free Flowing Powders, Granular & Pelleted Materials into Downstream Processes or Bag Filling Equipment.

Bag Sewing

Choice Bagging Equipment, Ltd. offers a wide variety of industrial portable bag sewers, sewing heads and pedestal mounted sewing heads.

Bag Sealing

Choice Bagging Equipment, Ltd. offers a variety of industrial bag sealers for paper and plastic bags.

Bag handling COnveyor

Choice Bagging Equipment, Ltd. manufactures multiple types of bag handling conveyors including: bag transfer conveyors, incline/transport conveyors, bag flattening conveyors, bag turner conveyors, bag kickers, bag closing conveyors, v-through conveyors, and bag discharge assemblies.

Bag palletizing System

These bag palletizing systems are versatile because the bag inflow can be added in any direction. The operator platform and auxiliary air table can also be reconfigured. Overall, this low-cost option requires very little floor space.