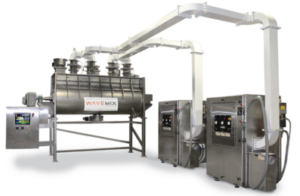

Blenders and Mixers

Marion

Marion Process Solutions is the leading global manufacturer of mixers, blenders, thermal processing equipment, and size reduction equipment, with more than 80 years of engineering expertise.

Insight

Expansive industry knowledge + unmatched engineering experience = individualized solutions that deliver best-in-class performance for decades.

Innovation

Imaginative engineering + superior quality = customized, sustainable, efficient process solutions.

Advantage

True end-to-end involvement + consultative technical expertise and customer service excellence = long-term competitive advantage.