BUCKET ELEVATORS

SWINGLINK -FOOD & DELICATE PRODUCT

Many of our clients work in the food and powder industries and have unique needs: Ensuring an efficient manufacturing process by eliminating threat to product integrity and risk of unsanitary conditions. We are pleased to offer these clients Swinglink bucket elevators that are designed with gentle handling and sanitation in mind.

Swinglink bucket elevators remain upright throughout the handling process to safeguard the integrity of your product. Smooth bucket surfaces eliminate product trap areas while the clean-in-place capabilities of the Swinglink provide for maximum cleanliness.

Swinglinks are available with carbon steel, stainless steel or plastic surfaces in all product contact areas. They offer the flexibility you require to accommodate your manufacturing needs, yet they are also designed for gentle and efficient handling. Swinglink bucket elevators safeguard product integrity and minimize spilling. In short, they provide our clients with the specifications they need to ensure operational proficiency.

ECONO-LIFT BUCKET ELEVATORS FOR FOOD & INDUSTRIAL

The Econ-o-Lift bucket elevator’s robust construction is built for durability and easy installation. It features a collapsing chain and 360-degree discharge with multiple discharge and inlet feeds for maximum flexibility. This bucket elevator can also be designed for food manufacturing applications with food-grade, stainless steel, or plastic conveyor surfaces that allow your company to comply with the regulatory standards specific to your industry.

With the Econ-o-Lift, buckets remain upright throughout the circuit reducing the probability for product spills and allowing the option for multiple discharge points from the lower rung of the bucket elevator. This will help minimize breakage from product discharge drop heights.

Additionally, the buckets feature a trailing curved lip that, when interlocked with the bucket in front and behind, allows the product being introduced into the Econ-O-Lift to flow directly and cleanly into each bucket cavity.

The result is flexible equipment that handles a variety of products for many different industries. For food and delicate products, the equipment is designed for gentle and efficient handling to protect the product and to reduce spillage. Gough Econ’s engineers have installed nearly 600 of these units to date and we continue to recommend them to our clients.

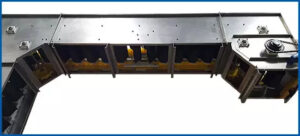

ELECON

Gough Econ is the only licensed global manufacturer of the Elecon™, the world’s only bucket conveyor that can move materials in any direction. No other conveying system in the world is as flexible as the Elecon. In addition to the typical vertical and horizontal movement, the Elecon bucket can make right or left turns. This multi-axis capability is a result of its patented chain design and wedge-shaped buckets. Dubbed as the “go anywhere” conveyor, the Elecon minimizes your system’s footprint and can handle virtually any circuit design imaginable.

The Elecon is one of our best known and most versatile bucket elevator designs—and we are pleased with how it helps clients increase their operational effectiveness. No matter what configuration you need, these bucket elevators are engineered to provide solid and robust components that withstand most environments.

SWINGLINK HEAVY DUTY

Gough Econ utilizes the most robust construction and components in the industry to ensure the reliability and durability of our Swinglink bucket elevators. The continuous chain and bucket design with overlapping bucket lips contribute to the adaptability of the Swinglink. With the strongest chain in the industry, the Swinglink provides durable, yet gentle, handling of a range of industrial goods.

Gough Econ has been recommending Swinglink products for decades, and for good reason. This equipment handles a variety of products for many different industries and is designed to resist wear and tear, even in harsh environments. Our customers are looking for efficiency, reliability, and confidence that their equipment will provide a good, long-term capital investment—and we know Swinglink to be an exemplary option in each of these categories.

HEAVY DUTY VERTICAL BUCKET ELEVATORS

One of the most efficient ways to elevate bulk materials vertically is with a bucket elevator. A Bucket Elevator consists of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. KWS designs and manufactures a wide variety of bucket elevators based on the characteristics of the bulk material and the process requirements.

KWS Bucket Elevators are custom designed for your application. Bulk material characteristics, capacity and overall height are considered when designing Bucket Elevators. KWS is an ISO 9001:2015 certified manufacturer. Every component and assembly is manufactured in the USA by highly skilled craftsmen. All KWS welders are certified in accordance with American Welding Society (AWS) Codes. KWS Bucket Elevators are manufactured to rigid quality standards.

CENTRIFIGAL BUCKET ELEVATORS

KWS provides a heavy-duty centrifugal-type bucket elevator. Chain-type bucket elevators have traditionally been used in applications such as coal handling because of their robust low-maintenance design. The KWS chain-type bucket elevator includes a heavy-duty, steel-bushed chain. These chains are designed to provide superior performance in the most severe working conditions. High strength, hardened pins, bushings, and sidebars offer excellent wear resistance, great fatigue resistance, and reduced chain elongation. The bucket elevator included heavy-duty engineering class sprockets utilizing Type C single, non-split hubs keyed with set screws to match the head and tail shaft’s diameter. The sprockets were provided with flame-hardened teeth providing superior wear resistance.

Advantages of Using Bucket Elevators

- Designed To Handle A Wide Variety Of Bulk Materials – From Average To Very Free-Flowing

- Many Different Bucket And Casing Sizes Available For Capacities Up To 15,000 Cubic Feet Per Hour

- Completely Enclosed For Dust And Weather-Tight Operation

- Inlet Section Can Be Control Fed Or Flood Loaded With Bulk Materials

CONTINUOUS BUCKET ELEVATORS

Though centrifugal bucket elevators are the most common design for elevating bulk materials, attempting to discharge a low-density bulk materials such as wood fiber would lead to much of it free floating within the elevator housing. A continuous bucket elevator allows the material to discharge by gravity and slide out of the bucket, using the back of the preceding bucket as a ramp. Such a controlled discharge is preferred to maximize transfer efficiency.

Available Features / Options

- Custom Engineered For Your Specific Application

- Wide Range Of Construction Materials – Carbon Steel, Stainless Steel And Abrasion-Resistant Alloys

- Belt And Chain Type Elevators Available To Meet Your Specific Requirements

- Screw-Type Or Internal Gravity Take-Ups Available