EAGLE

Quality. Assured.

MDX DETECTOR

DUAL ENERGY X-RAY

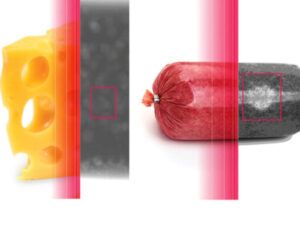

Material Discrimination X-ray (MDX) dual energy technology was introduced to the product inspection industry by Eagle Product Inspection in 2005, providing food processors with unprecedented contaminant detection capabilities. Advanced dual energy MDX is ideal for challenging products such as packages of shredded cheese, yogurts with added ingredients, bagged vegetables, bulk potatoes, dried figs and more.

Drop Gate

Reject

Removes packaged products from production lines identified as non-conformant with quality specifications. This mechanism can be used on most packaged products, some unpackaged products and is perfect for multilane applications. The drop gate reject device consists of pneumatic cylinders that pivot a gate down, dropping any products that do not meet predetermined quality specifications in the direction of the reject receptacle.

Deflection Flap Reject

Removes unpackaged bulk products from production lines identified as non-conformant with quality specifications. The Deflection Flap reject device consists of pneumatic cylinders that pivot multiple flaps which create an opening to drop the non-conformant bulk product in the direction of the reject receptacle. The Deflection Flap reject mechanism is specifically designed for bulk applications such as nuts, beans, peas, coffee and sugar. Deflection flap rejects are available in 1, 2, 4, 6 and 8 lane configurations.

Pack 720

Pro

Designed for x-ray inspection of large packaged products in boxes or cases and multilane applications in the Food, Pet Food, Pharmaceutical and Personal Care industries.

The Pack 720 PRO is simultaneously capable of performing following inline quality control checks:

- Contaminant detection

- Mass measurement

- Package integrity

- Component count

DAIRY X-RAY

INSPECTION SOLUTIONS

Eagle’s advanced inspection systems help manufacturers inspect more, finding foreign contaminants and ensuring proper portioning, placement, weight and package integrity to deliver the safest, highest quality products. Eagle equipment helps ensure the safety and integrity of ingredients and products across all stages of the dairy production process. From bulk flow (loose) products that may be added to dairy, such as nuts, grains, dried fruits and cereals, to unpackaged and packaged products, our inspection systems can handle dairy applications including sliced, block, and shredded cheese, spreads, yogurt, milk, and milk powders, and more.

pack 400 Hc 3-a dairy

Meets requirements for 3-A Sanitary Standard 75-01 for the dairy industry and is built for harsh washdown environments, including ingress protection compliance with IP69 specifications, making it ideal for inspecting raw products such as blocks of cheese.

With its advanced image analysis software, SimulTask™ PRO, the system simultaneously performs quality control checks:

- Superior contaminant detection

- Exceptional mass measurement for blocks of cheese

- Fill level verification

- Void detection in cheese

- Cap detection for drinkable yogurt or milk bottles

- Identify trapped food in seals for cheese packages

- Component count in sliced cheese packages

Simultask™ Pro image analysis software

SimulTask™ PRO takes the guesswork out of x-ray imaging, so food producers can focus on safety, quality, operational efficiency, and profitability. This customizable software can be tailored to your specific product applications with the flexibility to evolve with the ongoing demands food manufacturers face. SimulTask™ PRO advanced image processing algorithms provide high resolution, exceptional clarity and extraordinary detail. With the highest greyscale range of up to 65,535 values, you will see deeper contrast and subtle differences providing superior inspection results for your production line.

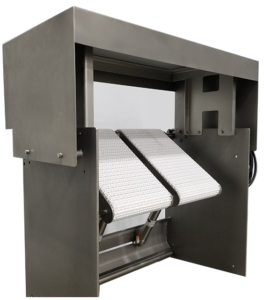

pack 430 Pro

Designed for x-ray inspection of mid-sized packaged products and multi-lane applications. The Pack 430 PRO is suitable for inspecting standard poly-wrapped products, as well as food packaged in foil or metalized film and provides 430 mm (16.9”) of detection coverage at the belt with high-speed imaging up to 120 meters per minute (400 FPM). The x-ray machine for the food industry is capable of multilane inspection which enables manufacturers to inspect multiple lanes of the same or dissimilar products, or alternatively use one lane for production and the other for rework.

It simultaneously performs the following quality control checks in a single pass with precisions and accuracy:

- Superior contaminant detection

- Mass measurement

- Package integrity

- Component counts

REJECT MANAGEMENT SYSTEM

MAXIMIZER RMI

Eagle’s MAXIMIZER RMI is designed to handle a variety of raw poultry products to detect and reject product contaminated with bones, metal or other foreign objects. The x-ray bone detection system is designed for easy cleaning in harsh washdown environments for fresh or frozen poultry where daily sanitization of equipment is mandatory. The MAXIMIZER RMI is an innovative solution designed to optimize the production process for poultry including chicken processing operations, saving time, resources, and reducing manual labor related to handling rejected products. Our system combines an enhanced x-ray inspection machine equipped with PXT™, and an automated reject management system, providing superior bone and metal detection while greatly minimizing false rejects. This poultry x-ray bone detection system has a small footprint and is the most hygienic and ergonomic on the market today. Our Eagle x-ray system is purpose-built to effortlessly disassemble and assemble making sanitation quick and easy.