Fox Venturi Products (Fox Valve) has been the leading global supplier of venturi eductors and venturi transport systems for dilute phase pneumatic conveying of powders, pellets, and bulk solids since 1963. Fox Eductors, also referred to as jet pumps, enable the use of low pressure air (below 14 psig or 1 bar) to be used to move powders, pellets, and bulk solids with no moving parts. These venturi eductor systems can be used to convey product at up to 15 tons per hour over distances up to 500 feet.

Fox Venturi Eductors – What Are They?

Fox Venturi Eductors are used to feed powders, pellets, and bulk solids into a pneumatic conveying system. Because they have no moving parts, they can – and often do! – operate almost entirely maintenance-free. Feedback from customers often reveals five, ten, or even fifteen years of maintenance-free operation.

How Are They Used In Pneumatic Conveying Systems?

Fox Venturi Eductors are used to introduce bulk solids such as powders, pellets, flakes, and particulates into positive pressure conveying systems. They offer end users and system designers a way to eliminate rotary valves from conveying systems where rotary airlocks/rotary valves simply cannot perform adequately. This often occurs with very fine, abrasive, fragile, or high-temperature solids.

Why Are Eductors Used In Pneumatic Conveying Systems?

Fox Venturi Eductors Have No Moving Parts – allowing for maintenance-free feeding of bulk solids. In applications involving fine, abrasive, or irregularly-shaped products, this is an enormous advantage. Replacement of existing rotary airlocks with venturi eductors makes for simpler, more reliable conveying systems. Designing with eductors from the beginning ensures the most reliable product feeding available.

No Blowback – All rotary airlocks/rotary valves have blowback – also known as fugitive dust or leakage. If the product conveyed is fine or abrasive, blowback can cause extreme wear problems. Even with free-flowing products, blowback can be a problem, causing bridging and housekeeping problems, or even an explosion hazard. When installed beneath baghouses, screw conveyors, or dust collectors, airlocks can be a major source of fugitive dust emissions, which are eliminated after a retrofit to Fox eductors.

No Mechanical Shearing/Product Damage – Eductors minimize the shearing, smearing or degradation of products common with rotary airlocks. And, of course, safety is simply not a concern with Fox eductors.

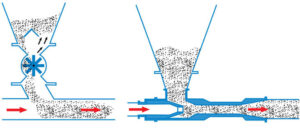

Eliminating the rotary airlock, left, with a Venturi eductor, right, permits

product feed with no moving parts for maintenance-free conveying.

Fox Eductor/Blower Sub-Systems

Fox Valve can provide almost all of the equipment necessary to enable easy, quick installation of a fully-guaranteed pneumatic transport system.

Conveying from Multiclones – One blower drives (16) Eductors, conveying ash at up to 900° F with No Moving Parts