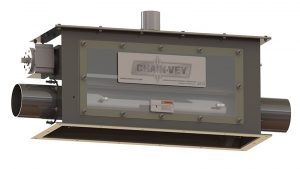

Drag Conveyors by Chain-Vey

Tube chain conveyor systems move products gently, efficiently, horizontally and vertically in dust-tight tubes without product degradation or declassification.

Conveyors for Foods and solid

Chain-Vey tubular drag conveyors can move almost any wet or dry food, powder, and bulk solid.

Tubular conveyor Capacities

Tubular drag conveyor systems offer flexible configurations and capacities. All of our systems are custom built, and are ideal for product flow as high as 2,000 cubic feet per hour (57 m3/hr).

175 ft3/hr or 5 m3/hr

3″ diameter drag chain conveyors are great for malted barley. It is the popular choice for seeds and crumbs as well.

650 ft3/hr or 18 m3/hr

4″ diameter drag chain conveyors are a great fit for green and whole bean roasted coffee, oats, pecans and almonds.

1,000 ft3/hr or 28 m3/hr

5″ diameter drag chain conveyors are great for moving pet food, breakfast cereal, peanuts, whole walnuts and cashews.

1,400 ft3/hr or 40 m3/hr

6″ diameter drag chain conveyors are great for any application in scaled process systems like ground coffee or bulk powder.

2,000 ft3/hr or 57 m3/hr

8” diameter drag chain conveyors are great for large scale operations; perfect for bulk ingredients, grains, and finished foods.

Designs

All of our tubular drag conveyor systems are robust, sanitary, gentle, and quiet. The robust, low-friction disks are designed for lower maintenance costs and energy consumption. Chain-Vey offers both standard Quiet Pucks and High-Efficiency Pucks for special application.

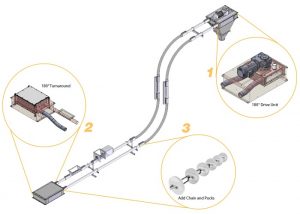

Common System Layouts

Common tubular drag designs each used for a particular stage in processing.

Inlets and Dischargers

Both advanced and simple designs for inlets and discharges, ensuring a reliable, low-breakage conveyance.

Tensioners and U-Track

Options that allow for extremely easy tube conveyor use, minimizing labor and loss of product.

Cable to chain-vey

Retrofit

Cable tube conveyor owners can replace their worn cables with new chain and discs as part of our retrofit kit. The kit is a simple and cost-effective solution to elevate the strength and reliability of an existing conveyor by using an unbreakable chain and application-specific optimized discs.

Automated clean in place options

Tube conveyor systems offer a wide array of cleaning options built around your product needs. This is why our tube conveyors are preferred in many industries with critical sanitation requirements, passing all swab tests including ATP, Aerobic Plate Count, Coliform, and Bi-Luminous.