Pneumatic Vacuum Conveying

Light Duty Applications

VOLKMANN’s high quality, pneumatic vacuum conveyors transport fine food powders, chemicals, granules, pellets, tablets and other small components under vacuum in lean, dense phase or plug flow conditions without damage or abrasion.

A Volkmann Vacuum Conveyor offers the Food, Pharmaceutical and Chemical industries:

- user friendly systems with safe material transfer

- easy material aspiration and dust-free loading of machines

- gentle dense phase conveying, no segregation of material mixtures

- optimum hygiene conditions

- reliable filter systems in GMP quality

- simple installation and operating

- low energy consumption

- favorable investment- and operating costs

High Capacity Conveying

Dilute & Dense Phase

In dilute phase systems, materials are suspended in the conveying air stream. This occurs when materials are conveyed at a velocity above the saltation, or minimum suspension velocity, of the material. For materials to reach dilute phase, conveying air velocities of 3,200 to 7,000 feet per minute are required. Because these systems convey materials at higher velocities, they’re typically used to convey materials that are not susceptible to degradation or not abrasive in nature. Often times, the type of material you are conveying, how far the material is being conveyed or the condition the material is in when conveyed, will determine which application is right for you.

In dense phase systems, material is not suspended in the conveying air stream. This occurs when the conveying air stream is between 1,200 to 2,000 feet per minute or below the minimum saltation value.

Eductors

HOW ARE THEY USED IN PNEUMATIC CONVEYING SYSTEMS?

Fox Venturi Eductors are used to introduce bulk solids such as powders, pellets, flakes, and particulates into positive pressure conveying systems. They offer end users and system designers a way to eliminate rotary valves from conveying systems where rotary airlocks/rotary valves simply cannot perform adequately. This often occurs with very fine, abrasive, fragile, or high-temperature solids.

FOX EDUCTOR/BLOWER SUB-SYSTEMS

Fox Valve can provide almost all of the equipment necessary to enable easy, quick installation of a fully-guaranteed pneumatic transport system.

Conveying from Multiclones – One blower drives (16) Eductors,

conveying ash at up to 900° F with No Moving Parts

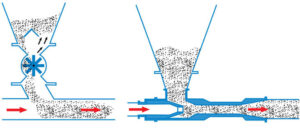

Eliminating the rotary airlock, left, with a Venturi eductor, right, permits

product feed with no moving parts for maintenance-free conveying.